Every once in a while we enthusiastically take on tasks that are special for one reason or another.

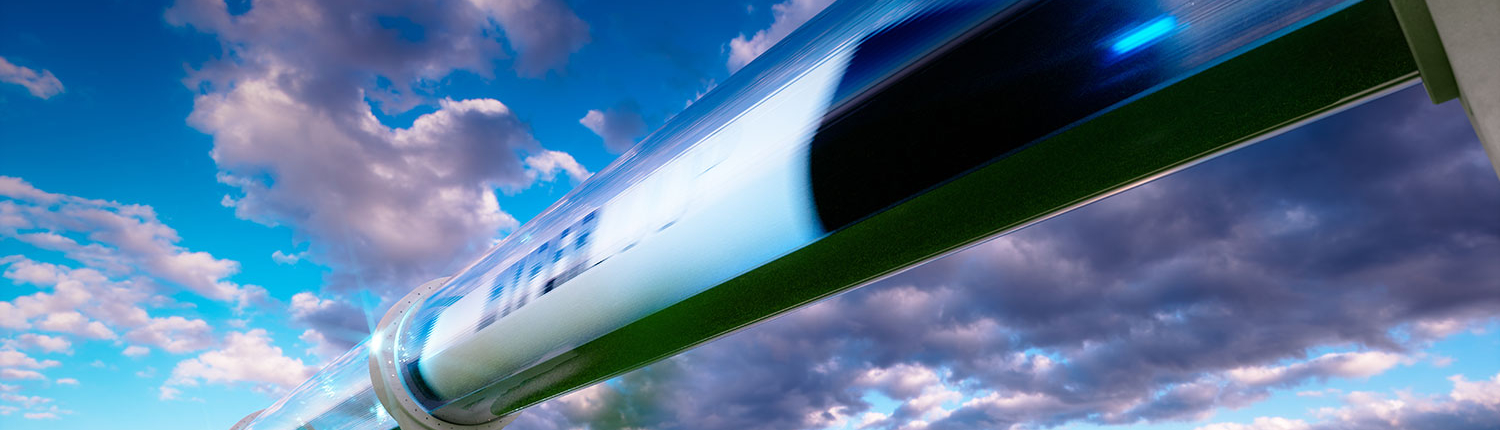

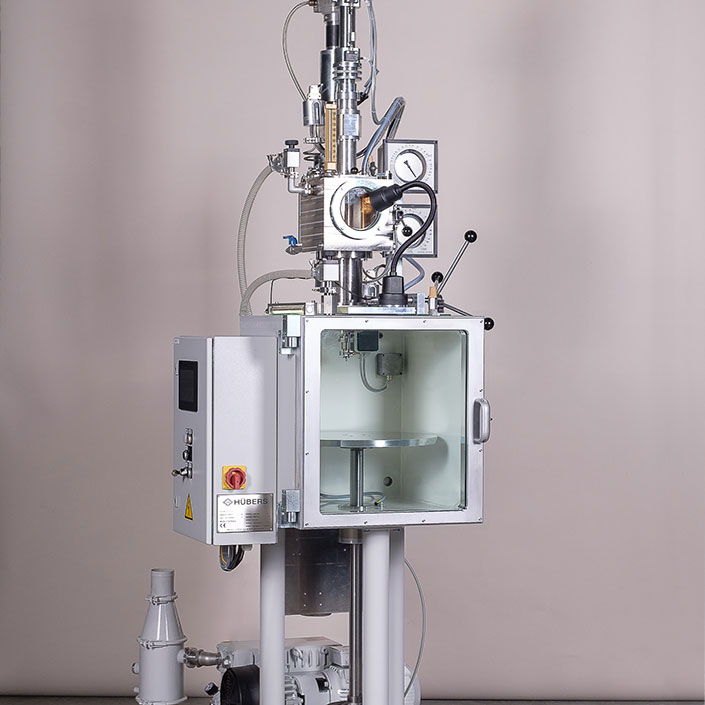

For example, there is the casting of magnetic coils for the JR-Maglev magnetic levitation train of the Japanese railroad consortium. Here, new standards have been set, especially in terms of production capacity, since the aim is to “magnetize” an entire country. Our systems have been in continuous operation in Tokyo since 2015 – end open. Speaking of high-speed transportation systems: In our technical development center, casting processes have already been developed for an even more ambitious mobility concept, the Hyperloop.

Other examples, such as the casting of plastic spectacle lenses or the production of washstands and sinks made of epoxy resin using the APG process, have absolutely nothing to do with electrical insulation.

And air passengers come into contact with HÜBERS technology not only in the form of infused composite components of the tail unit, but also in the quietest place in the cabin, where vacuum generators encapsulated on HÜBERS systems reliably perform their important service for cabin pressure.