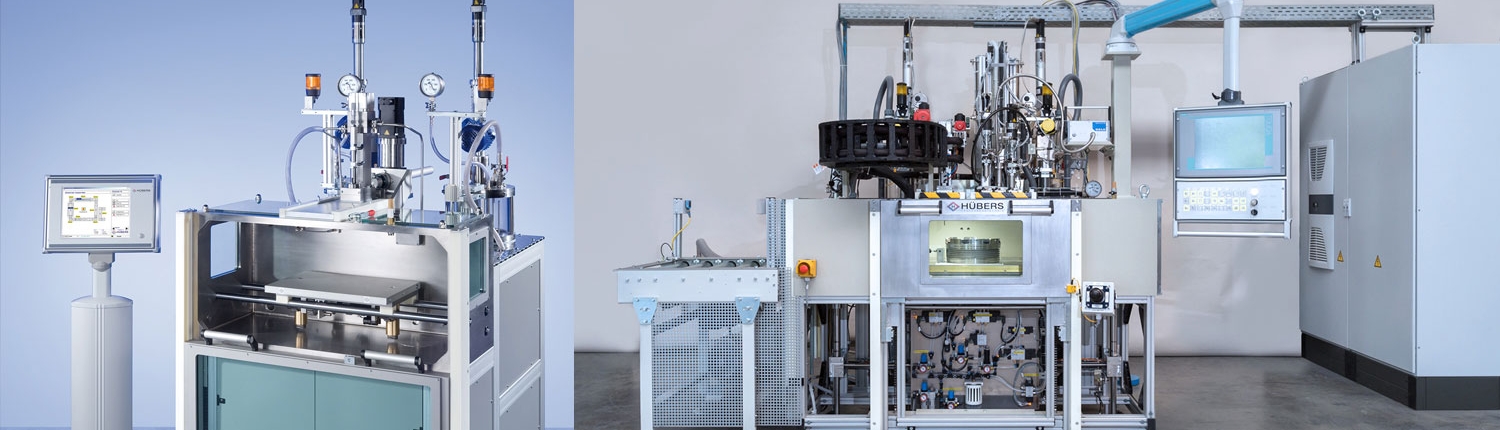

The micro-series systems ensure that your production reliably meets the particularly high requirements in terms of precision and casting geometry.

Due to its extraordinarily high dosing accuracy, especially with the smallest casting material quantities, it is particularly suitable for high-end or clean room applications, even when using high-priced casting materials.

In addition, the design and material of the dosing mixers make it quick and easy to change the casting material. In connection with the integrated design as a complete casting system, this flexibility also makes micro systems a perfect system for the (further) development of casting applications.

- exact dosing of smallest amounts of casting material, tolerance less than 0.01 g

- motion casting from simple axis movements to complex, three-dimensional trajectories

- glass-stainless steel design of the dosing mixer vessels enables direct observation of casting material preparation and easy cleaning

- vacuum mixing, dosing and casting system in integrated design

Download the micro-flyer here

Motion Casting and Casting Trajectory Control

- CNC programming via graphical user interface based on CAD/CAM

- interpolation of mathematical functions and tables, linear interpolation

- transfer and adaptation of casting trajectories also possible from drawings and pictures directly on the operating screen