The exact adherence to the mixing ratio of the material components in the casting compound can be controlled via the real-time recording of the dosing pressures.

In HÜBERS systems this is achieved on the one hand by permanently monitoring the synchronous operation of the dosing pumps and their pistons’ traveling distances.

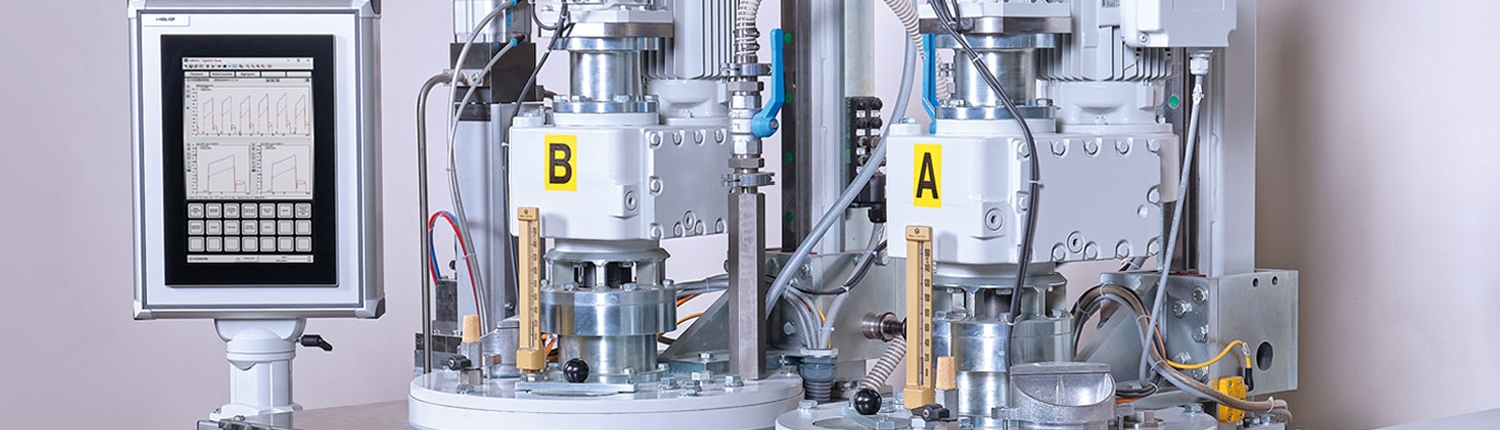

In addition, we use our patented Dosing Control Unit (DCU) in order to obtain absolute certainty regarding the dosage. The DCU evaluates the current process data independently of the system control and thus offers complete monitoring of the actual pressure curves.

The Dosing Control Unit carries out pressure, quantity and time comparison monitoring of the dosing pumps.

- The pressure curves of the pumps are monitored during each dosing process.

- The data is visualized on the screen in real time.

- Deviations are reported immediately.

- The data is being logged.

- In the event of faults, the process is automatically stopped and a cause analysis is performed.

In this way we achieve

- the immediate, visual monitoring of all current process parameters; deviations from target values are reported.

- the traceability of the course of the process.

- maximum process reliability.

- perfect quality assurance for the dosage.